Fundamentals

The Meroitic Iron Industry represents a pivotal chapter in ancient African technological prowess, casting a warm glow on the ingenuity of the Kushite civilization. At its core, the Meroitic Iron Industry refers to the systematic and large-scale production of iron that flourished in the ancient city of Meroe, the southern capital of the Kingdom of Kush. Situated on the east bank of the Nile, approximately 200 kilometers north of modern Khartoum in Sudan, Meroe became a celebrated hub for metalworking from the third century BCE through the fourth century CE. This industrial activity was foundational to the prosperity and enduring power of the Kushite state, allowing it to sustain its economy and military strength for centuries.

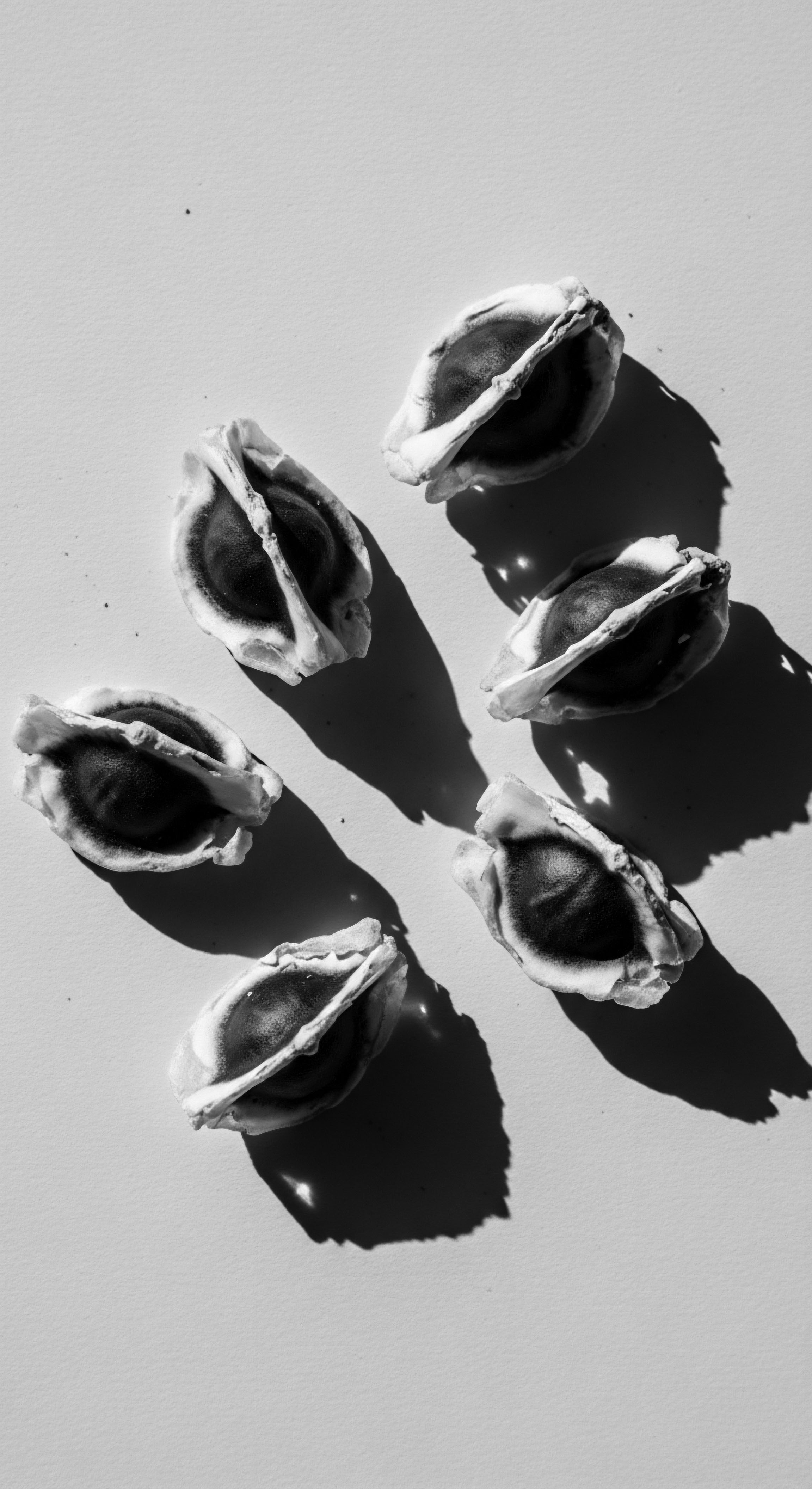

The process at the heart of this industry involved a technique known as bloomery smelting. This method, widespread across ancient Africa, transformed iron ore ❉ a naturally occurring mineral rich in iron oxides ❉ into a usable form of metallic iron. The furnaces, often constructed from clay and fueled by charcoal derived from abundant local hardwoods, reached temperatures sufficient to reduce the iron ore.

The outcome was a spongy mass of iron, or “bloom,” which still contained impurities and needed further refinement through hammering and reheating. This early form of iron was distinct from cast iron and was then shaped into various tools, weapons, and objects that shaped daily life and cultural expression.

The vast mounds of slag ❉ a glassy byproduct of the smelting process ❉ that still dot the landscape of Meroe stand as enduring testaments to the sheer scale of this ancient industrial endeavor. These remnants, sometimes stretching for kilometers, have captivated scholars for over a hundred years, prompting initial interpretations of Meroe as the “Birmingham of Africa” due to its seemingly immense iron production. While the exact scale of export and the full scope of its economic impact remain subjects of ongoing academic inquiry, the presence of these substantial deposits clearly indicates a well-organized and productive metallurgical tradition within the Meroitic kingdom.

The meaning of the Meroitic Iron Industry reaches beyond mere technological achievement; it embodies a sophisticated understanding of material science, resource management, and social organization that sustained a powerful African civilization. It reflects the deep connection between a people and their environment, where readily available iron ore and timber resources were skillfully harnessed to create a foundation for societal development.

Intermediate

The Meroitic Iron Industry stands as a profound testament to ancient African innovation, its methodologies extending far beyond rudimentary practices. This system of iron production was characterized by a specific variant of the bloomery process, often involving bellows-driven furnaces that allowed for regulated air supply and higher temperatures. These furnaces, which could reach heights of up to 2 meters, were frequently situated within dedicated workshop spaces, indicating a structured and specialized industrial activity.

Archaeological evidence from sites like Meroe and nearby Hamadab reveals a Kushite iron production tradition spanning over a millennium, from as early as the seventh century BCE to the sixth century CE. While the precise chronology of ironworking at Meroe has been a subject of scholarly discussion, significant activity was certainly underway by the middle of the first millennium BCE. The early focus of excavations was on temples and monumental architecture, leaving the immense slag heaps largely unexplored until more systematic investigations began in the mid-20th century. These later studies unearthed crucial details about furnace designs, bellow pots, and the surrounding workshop areas, offering a clearer understanding of the Meroitic metalworking practices.

Meroitic ironworking, with its specialized furnaces and systematic ore processing, signifies a sophisticated industrial legacy that sustained the Kushite civilization for centuries.

The impact of this industry on the Meroitic kingdom was considerable. Iron tools provided its farmers with superior implements for agriculture, promoting more efficient cultivation of crops like sorghum and millet. This enhanced agricultural productivity potentially supported an increasing population and allowed for a more sedentary lifestyle, even in areas beyond the immediate Nile floodplain where summer rains were a factor. The production of iron also supplied the Kushite armies with robust weapons, playing a part in their territorial defense and strategic endeavors.

Beyond its practical applications, the Meroitic Iron Industry held significant social and cultural weight. Blacksmiths across African cultures, including those in regions like Meroe, were often held in high regard, possessing a unique social status. Their knowledge and skills, which transformed raw earth into usable metal, were frequently viewed as possessing spiritual or superhuman abilities.

The act of smelting itself was often surrounded by rituals and taboos, with deep symbolic meanings attributed to the process. This elevates the Meroitic Iron Industry beyond a mere economic activity, framing it as a profound expression of communal belief and a connection to unseen forces.

The production was not always uniform throughout Meroe’s long history. Archaeological data suggests periods of reorganization within the city’s industrial base, with evidence pointing to intense iron production in the early (Napatan) and late (late/post-Meroitic) periods, with less activity during the time when Meroe was the primary capital of Kush. This ebb and flow hints at a dynamic economic landscape, perhaps influenced by shifts in trade routes, political priorities, or environmental factors such as the availability of timber for charcoal.

- Bloomery Smelting ❉ The prevalent method, involving heating iron ore and charcoal in furnaces to produce a solid, spongy mass of iron known as a bloom.

- Bellows-Driven Furnaces ❉ Crucial for achieving the high temperatures required for smelting, these often conical or cylindrical structures directed air into the furnace.

- Slag Mounds ❉ The substantial accumulations of waste material, serving as archaeological markers of the extensive iron production at Meroe.

Academic

The Meroitic Iron Industry, in its academic interpretation, represents a complex archaeometallurgical phenomenon, demanding a sophisticated understanding of ancient technology, economic systems, and socio-cultural dynamics within the Kingdom of Kush. The term encompasses the entire chaîne opératoire of iron production, from the procurement of raw materials such as iron ore and timber, through the smelting process, to the forging of finished artifacts and the management of industrial waste. The considerable volume of slag heaps at Meroe, particularly the colossal formations like MIS1 ❉ 4, compels scholarly inquiry into the logistical demands, labor organization, and environmental impact of such sustained industrial activity.

A persistent scholarly discourse surrounds the origin of iron metallurgy in Sub-Saharan Africa, with Meroe frequently cited as a potential center of independent innovation or diffusion. While some earlier cultural-historical perspectives posited a northern diffusion from Egypt or the Mediterranean, more recent radiocarbon dating evidence from Meroe suggests ironworking by the sixth century BCE, making it one of the oldest dated sites for iron production in Sub-Saharan Africa. This chronology, coupled with the distinct metallurgical traditions observed in Meroitic artifacts ❉ characterized by high phosphorus and arsenic content, sophisticated forge work, and the strategic placement of steel at working edges ❉ advocates for a locally developed, highly adapted approach.

The absence of martensite in Meroitic artifacts, despite the presence of steel, underscores a unique metallurgical pathway distinct from contemporaneous traditions in other regions. This suggests a profound mastery of the bloomery process, tailored to local ores and fuel sources.

The Meroitic Iron Industry’s distinct metallurgical signatures point to a nuanced understanding of materials, affirming ancestral innovation rather than simple technological replication.

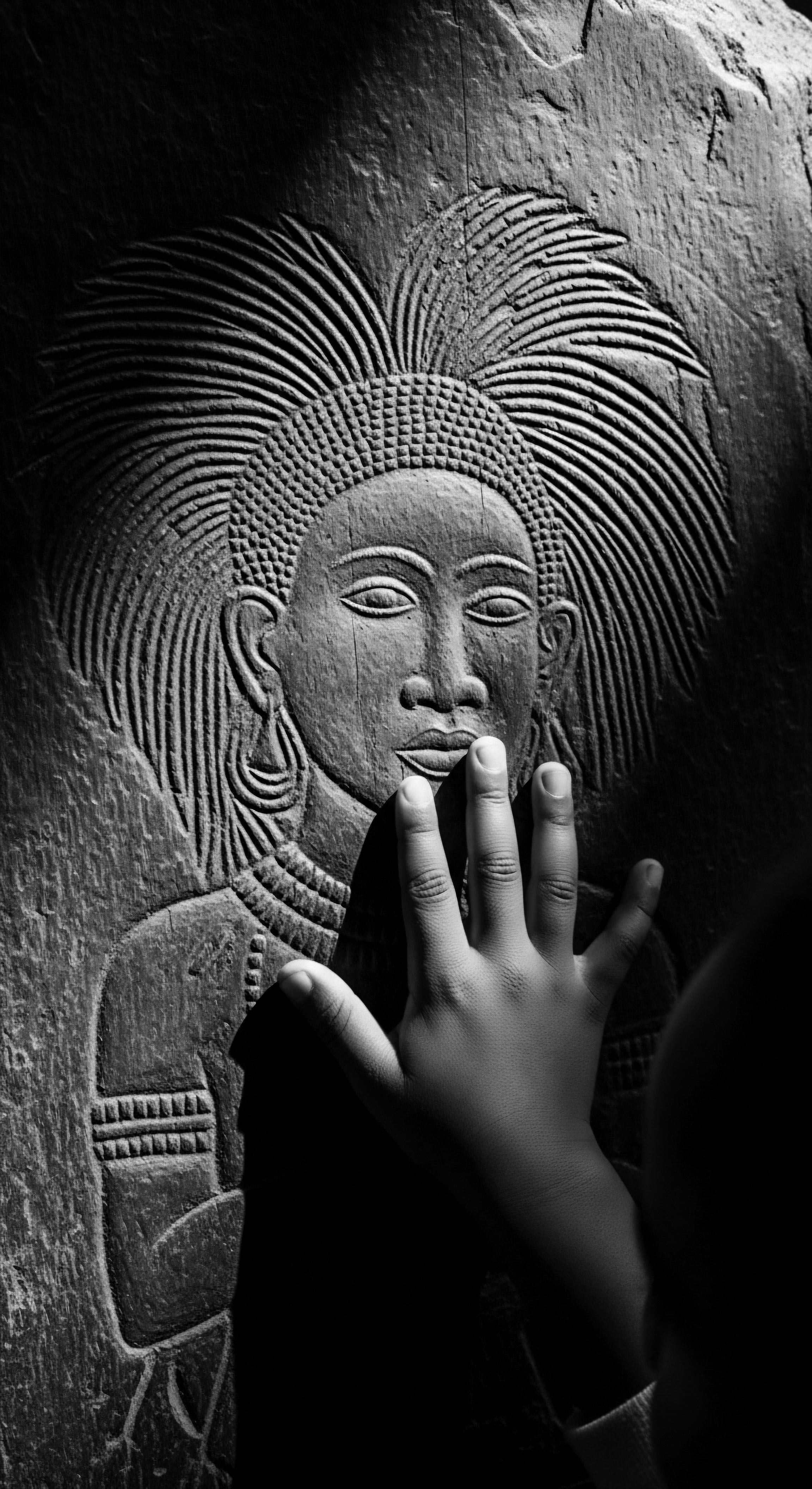

The true meaning of the Meroitic Iron Industry extends into the very fabric of human experience and cultural identity, particularly as it relates to textured hair heritage. The deeply symbolic significance of iron production across various African societies offers a compelling lens through which to comprehend this connection. Across many African cultures, the transformative act of extracting iron from earth and fire was often likened to the miraculous process of procreation.

Furnaces were frequently designed to resemble the female body, with the ore placed in the “belly” of the structure, conceptually birthing the bloom. This powerful metaphor suggests a profound reverence for creation and the generative forces of life.

Consider the ancient Kono people of Sierra Leone, whose blacksmiths, like their Meroitic counterparts, were masters of this transformative art. The Kono understood iron smelting as a deeply spiritual process, where the furnace symbolized the womb, and the resulting iron bloom represented a newborn, imbued with life force. This ancestral practice, documented by scholars like Terry S. Childs, reveals a cultural context where the very act of metal production was intertwined with concepts of vitality and continuance (Childs, 1998, pp.

29-30). This parallels the Meroitic context, where iron’s inherent strength and its metaphorical connection to life would have seamlessly woven into the cultural understanding of physical attributes, including hair. Textured hair, with its inherent strength, unique growth patterns, and ability to be sculpted into diverse, intricate styles, has always been a powerful symbol of identity, lineage, and life force within Black and mixed-race communities. Just as the Meroitic artisans harnessed the raw power of iron to shape their world, so too did ancestral communities understand hair not merely as a biological outgrowth, but as a living extension of self, capable of transmitting spiritual energy and signifying belonging. The resilience inherent in iron, forged in intense heat, mirrors the remarkable resilience of textured hair, which endures and thrives despite historical attempts to diminish its natural splendor.

The iron industry’s role in the Meroitic economy, therefore, supported a society where such cultural values could flourish. Iron was used for utilitarian items like hoes and weapons, but also for personal adornment, including jewelry and potentially tools for intricate hair styling. While direct archaeological evidence of specific iron hair tools from Meroe is scarce, the prevalence of elaborate hairstyles in ancient Nubian and Egyptian iconography, including the adoption of the “Nubian wig” by figures like Queen Nefertiti, implies sophisticated grooming practices that would have benefited from durable tools.

The very strength and permanence of iron, a material that defined their state, would have resonated with the cultural value placed on robust and expressive hairstyles, which served as powerful visual statements of status, community, and individual artistry. This cyclical relationship ❉ where a robust iron industry enabled societal stability, which in turn allowed for the flourishing of cultural practices such as elaborate hair artistry ❉ delineates the profound interconnectedness of material culture and heritage.

The distribution of Meroitic iron products, although debated in terms of scale, may have extended to Egypt and potentially southwards, indicating its importance in regional trade networks. This economic influence contributed to Meroe’s position as a significant cultural nexus along the Nile Corridor, where knowledge and practices, including those surrounding appearance and identity, were exchanged and adapted. The sophisticated and high-quality forge work of the Meroites, noted as unmatched by some contemporary African societies, underscores a profound understanding of material properties and their manipulation.

Understanding the Meroitic Iron Industry, then, requires us to consider how this deep material knowledge intersected with the spiritual, the social, and the aesthetic. The strength of iron, its life-giving symbolism, and its application in creating objects of utility and beauty, all contribute to a rich tapestry of heritage that still speaks to us through the resilience and artistic expression embodied in textured hair today.

The enduring legacy of the Meroitic Iron Industry also presents a compelling case for the independent development of complex metallurgical technologies in Africa. Dates from sites in Nigeria, such as Taruga, show ironworking by the 5th to 3rd centuries BCE, and even earlier dates from locations like Lejja (Nigeria) and Obui (Central African Republic) suggest iron metallurgical development as early as the third millennium BCE. This challenges diffusionist models that once suggested iron technology always spread from Eurasia, reinforcing the deep, indigenous roots of African metalworking expertise. The Meroitic contribution stands as a powerful example of this African self-determination in technological advancement.

The sociopolitical influence of iron was also undeniable. The control over iron production and distribution contributed to centralized power within the Meroitic empire. Metalworkers, as highly specialized artisans, were not only admired for their skills but also feared for their perceived proximity to supernatural forces, their craft often integrated into religious beliefs and political structures. This symbiotic relationship between craft and power further illustrates the comprehensive nature of the Meroitic Iron Industry, shaping not just physical objects, but also social hierarchies and spiritual understandings.

- Archaeometallurgical Analysis ❉ Examination of slag, furnaces, and artifacts to understand production methods, efficiency, and material composition.

- Chronological Dating ❉ Radiocarbon dating of associated materials to establish the timeline of iron production, revealing its significant antiquity in the region.

- Cultural Contextualization ❉ Interpreting the industry within broader Meroitic and African belief systems, including the symbolic and social roles of iron and blacksmiths.

Reflection on the Heritage of Meroitic Iron Industry

The echoes of the Meroitic Iron Industry reverberate across time, speaking not only of ancient technologies and economic might but also of a profound relationship with the earth, the spirit, and the very expression of self. As we contemplate the vast slag mounds of Meroe, we are reminded of a civilization that understood the profound connections between the material world and the intangible spirit. This understanding is a cherished aspect of ancestral wisdom, often recognizing the vital forces that flow through all of existence ❉ including the very strands of our textured hair.

The symbolic power of iron, its resilience and transformative capacity, aligns beautifully with the narrative of Black and mixed-race hair. For generations, textured hair has stood as a symbol of strength, adaptability, and an undeniable heritage, much like the enduring quality of iron. Just as the Meroitic blacksmiths carefully worked the bloom, extracting purity and potential from raw ore, so too do we, through our ancestral practices and modern care, cultivate the health and beauty of our hair, drawing out its inherent strength and allowing its unique form to unfurl.

This journey from elemental biology to living tradition, from the earth’s iron ore to the sculpted coils and intricate braids that adorn us, illustrates a continuous dialogue between past and present. The Meroitic Iron Industry is not a distant, static relic; it is a vibrant reminder of the ingenuity and cultural depth that flowed from the heart of Africa. It encourages us to look at our own hair journeys with renewed appreciation, seeing in each strand a connection to ancient wisdom, a testament to enduring resilience, and a canvas for expressing our unbound helix of identity. The meticulous craft of smelting, the patience in forging, and the celebratory adornment with metals speak to a legacy of care and intention ❉ a tender thread that connects us to our foremothers and forefathers who understood the power of creation in all its forms.

References

- Childs, Terry S. (1998). “The Archaeology of Iron: The Iron Age in West Africa.” In The History of Iron in Africa.

- Carey, Chris, Stremke, Frank, & Humphris, Jane. (2019). “The ironworking remains in the royal city of Meroe: new insights on the Nile Corridor and the Kingdom of Kush.” Antiquity, 93(368), 432-449.

- Humphris, Jane. (2014). “The ancient iron mines of Meroe.” Journal of African Archaeology.

- Humphris, Jane & Scheibner, F. (2017). “Iron Smelting in Sudan: Experimental Archaeology at The Royal City of Meroe.” Journal of Archaeological Science: Reports, 19, 386-395.

- Millet, N. B. & Kelley, J. A. (1982). “Meroitic Iron.” Expedition Magazine, 24(1), 45-47.

- Pope, J. (2014). The Socio-Politics of the Napatan Period in Kush.

- Reisner, G. A. (1923). Excavations at Kerma, Parts IV-V.

- Schmidt, Peter R. (1997). “Iron Technology in East Africa: Symbolism, History, and Archaeology.” Indiana University Press.

- Shinnie, P. L. (1967). Meroe: A Civilization of Sudan.

- Shinnie, P. L. & Kense, F. J. (1982). “Meroitic Iron Working.” Journal of Field Archaeology, 9(1), 1-22.

- Török, L. (1997). The Kingdom of Kush: Handbook of the Napatan-Meroitic Civilization.

- Wainwright, G. A. (1945). “Iron in the Napatan and Meroitic Ages.” Sudan Notes and Records, 26, 20-21.