Fundamentals

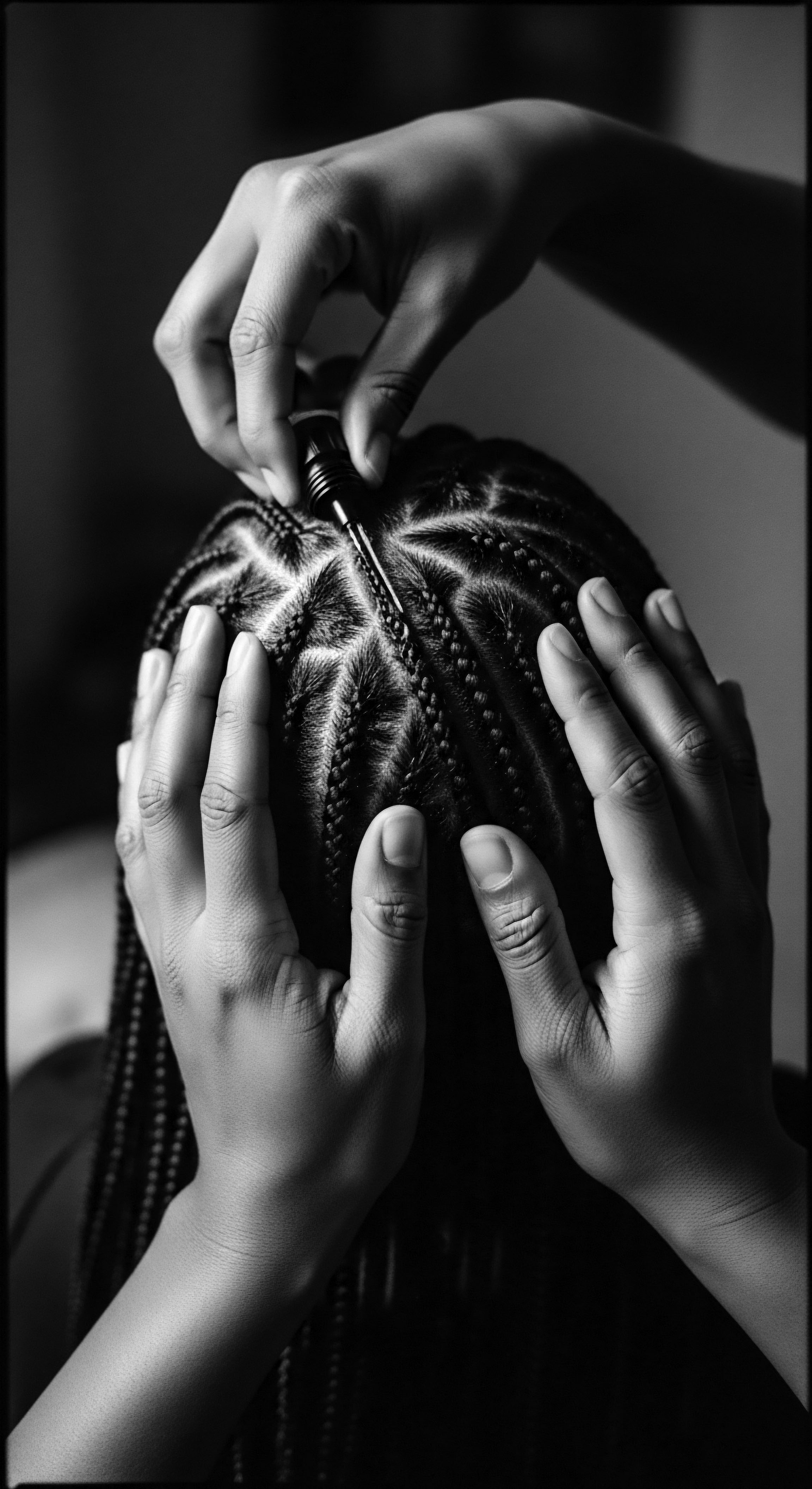

The Castor Oil Processing represents the meticulous journey of transforming the seeds of the Ricinus communis plant, commonly known as the castor bean, into the versatile oil revered across continents and generations. This transformation, a blend of ancient wisdom and contemporary understanding, is more than a mere mechanical operation; it is a cultural artifact, particularly within the narrative of textured hair heritage. The fundamental meaning of this processing involves extracting the oil from the castor bean, a seed rich in triglycerides, predominantly ricinoleic acid, which gives the oil its distinct qualities.

From the earliest records, dating back to ancient Egypt around 4000 BCE, the castor plant held a place of significance, its oil utilized for lamps, medicinal salves, and even cosmetics. This historical presence across diverse cultures underscores the enduring human connection to this botanical gift. The initial understanding of Castor Oil Processing, therefore, is rooted in these early applications, where the oil’s practical and therapeutic attributes were discovered through hands-on engagement with the plant. The earliest processing methods were elemental, relying on manual labor and simple tools to liberate the precious liquid from its protective casing.

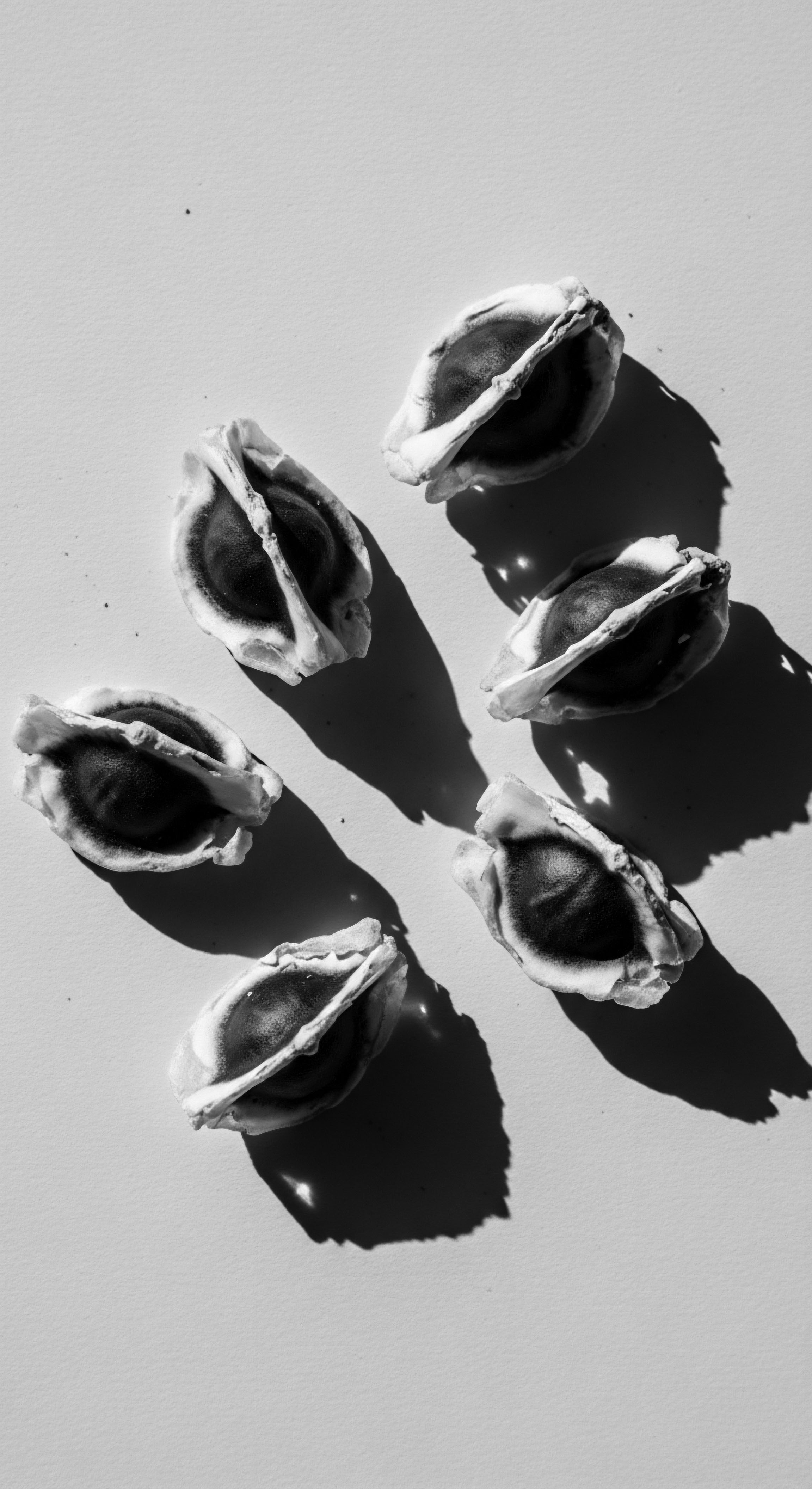

Understanding Castor Oil Processing at this foundational level means appreciating the plant itself, the Ricinus communis, which is native to the Ethiopian region of tropical East Africa and parts of Asia. Its resilience, thriving in semi-arid climates, made it accessible to communities where other crops might falter, contributing to its widespread adoption. The processing, at its simplest, begins with harvesting the seed pods, followed by shelling to access the beans. These beans then undergo various steps to release the oil, a process that, even in its most basic form, requires careful attention to yield a usable product.

Castor Oil Processing, at its core, is the ancestral alchemy of transforming a humble seed into a liquid legacy, deeply intertwined with human ingenuity and the nurturing of textured hair across time.

Initial Extraction Methods: Echoes from the Source

The earliest forms of Castor Oil Processing were born from necessity and a profound understanding of natural resources. These methods, passed down through oral traditions and practical demonstration, often involved a series of manual steps designed to break down the seed structure and separate the oil. The seeds, once collected, were typically dried, sometimes under the sun, to facilitate the removal of the hull. This initial dehulling, often done by hand or with rudimentary tools, exposed the oil-rich kernel.

- Harvesting and Drying ❉ The journey begins with gathering the mature seed pods, allowing them to dry naturally until they split open, releasing the seeds. This initial step is crucial for efficient dehulling.

- Dehulling and Winnowing ❉ After drying, the outer shell is removed, often by pounding or crushing, followed by winnowing to separate the lighter shell fragments from the heavier seeds. This stage prepares the seeds for oil extraction.

- Crushing and Grinding ❉ The dehulled seeds are then crushed or ground into a paste. This mechanical action ruptures the oil-containing cells within the seed, making the oil accessible for collection.

- Heat Application and Separation ❉ Traditional methods often involved applying heat, such as boiling the ground paste with water. The heat helps to coagulate proteins and release the oil, which then floats to the surface for skimming. This thermal treatment is a defining characteristic of many traditional castor oil preparations, particularly the dark, nutrient-rich varieties cherished in textured hair communities.

These steps, though seemingly simple, represent a sophisticated empirical science developed over millennia. The precise timing of drying, the consistency of grinding, and the temperature during boiling all influenced the quality and yield of the oil. For communities relying on this oil for health, sustenance, and beauty, mastering these processes was a vital skill, linking generations through shared knowledge and practice. The traditional methods of processing, especially those involving roasting the beans, give rise to the distinctive dark color and nutty aroma of certain castor oils, such as Jamaican Black Castor Oil, which is particularly revered within textured hair care traditions.

Intermediate

Moving beyond the foundational understanding, Castor Oil Processing at an intermediate level delves into the variations in extraction methods and their impact on the oil’s characteristics, particularly its relevance to textured hair heritage. The term ‘processing’ here begins to differentiate between the ancient, often fire-roasted methods that yield darker, more alkaline oils, and the modern cold-pressing techniques that produce lighter, clearer varieties. This distinction is not merely cosmetic; it carries historical and cultural weight, deeply tied to the traditions of Black and mixed-race hair care. The processing meaning extends to the nuanced techniques employed to maximize the oil’s therapeutic and cosmetic potential.

Historically, the traditional processing of castor oil, particularly the method associated with Jamaican Black Castor Oil (JBCO), involves roasting the castor beans before pressing. This roasting imparts a distinct dark color and a slightly smoky aroma to the oil, along with a higher ash content due to the roasted plant material. This ancestral technique, believed to have been brought to the Caribbean by enslaved Africans between 1740 and 1810, represents a profound act of cultural preservation and adaptation.

Faced with the brutality of enslavement and the systematic stripping of their heritage, these communities held onto their traditional knowledge of plants and healing practices, including the intricate process of making castor oil. The processing, in this context, was not merely about oil production; it was about sustaining health, community, and identity.

The variations in Castor Oil Processing are not just technical differences; they are living testimonies to cultural resilience, each method telling a story of adaptation and the enduring power of ancestral wisdom.

Traditional and Modern Processing: A Dialogue of Generations

The contrast between traditional, often fire-roasted methods and modern cold-pressing techniques offers a window into the evolution of Castor Oil Processing. Cold-pressed castor oil, typically pale yellow and nearly odorless, is produced by mechanically pressing the raw seeds without the application of external heat. This method aims to preserve the oil’s delicate fatty acids and nutrients, yielding a product often favored for its purity in contemporary cosmetic and pharmaceutical applications.

The traditional processing of Jamaican Black Castor Oil, by contrast, is a multi-step, labor-intensive affair that speaks volumes about ancestral resourcefulness. A study on traditional methods of castor oil extraction in Nigeria, for instance, details a nine-step process that includes collection, shelling, dehulling, boiling, drying, grinding, mixing with water, boiling again to extract, scooping, and finally, drying the oil by heating. This rigorous sequence, particularly the roasting and boiling, is believed to contribute to the oil’s unique composition and perceived efficacy for textured hair.

The significance of this traditional processing extends beyond the physical product. For generations, the making of JBCO was a communal activity, often passed down through women, serving as a source of income and a means of cultural continuity in rural villages. This practice highlights how Castor Oil Processing is intertwined with socio-economic structures and the preservation of indigenous knowledge systems within the African diaspora.

The Ricinoleic Acid Story: A Scientific Affirmation of Ancestral Wisdom

At the heart of castor oil’s properties lies ricinoleic acid, a unique hydroxylated fatty acid that constitutes approximately 90 percent of its composition. This chemical compound is responsible for many of the oil’s acclaimed benefits, including its emollient, anti-inflammatory, and antimicrobial attributes. The understanding of Castor Oil Processing at this level involves appreciating how these traditional methods, through roasting and boiling, might influence the bioavailability or stability of this crucial compound, even if the ancestral practitioners did not possess the vocabulary of modern chemistry.

Modern scientific inquiry has begun to illuminate the mechanisms behind castor oil’s effectiveness for hair health, often validating the observations made by generations of ancestral healers and hair care practitioners. For instance, ricinoleic acid has been studied for its potential to inhibit prostaglandin D2 (PGD2) synthase, a molecule implicated in hair loss. While more human studies are needed to fully confirm these effects on hair growth, this scientific alignment provides a compelling bridge between ancient practices and contemporary understanding.

It affirms that the careful processing techniques developed by ancestors, whether through intuition or generations of empirical observation, yielded a product with demonstrable biological activity. The historical use of castor oil for thickening hair, stimulating growth, and soothing scalp conditions across African and Afro-diasporic communities gains a new layer of appreciation through this scientific lens.

Academic

The academic definition of Castor Oil Processing transcends a mere description of extraction techniques, instead offering a rigorous examination of the biochemical, ethnobotanical, and socio-economic dimensions inherent in transforming Ricinus communis seeds into oil. This intellectual inquiry dissects the processes, distinguishing between methodologies and their resultant chemical profiles, while simultaneously grounding these technical specificities within their profound historical and cultural contexts, particularly as they pertain to textured hair heritage. Castor Oil Processing, in this scholarly light, is understood as a complex agro-industrial activity, ranging from artisanal, community-driven practices to large-scale commercial operations, each bearing unique implications for product characteristics, sustainability, and the communities involved. The meaning of this processing is thus multifaceted, encompassing not only the chemical alteration of the seed but also the cultural meaning it accrues through generations of human interaction.

At its most precise, Castor Oil Processing refers to the systematic series of physical and chemical operations applied to the seeds of the castor plant (Ricinus communis L.) to isolate and refine the oil. This process fundamentally aims to separate the oil, which constitutes between 40% and 60% of the seed’s mass, from the solid biomass and any undesirable compounds, including the highly toxic ricin protein, which is not present in the oil itself. The primary chemical component of castor oil, ricinoleic acid, a hydroxylated fatty acid, is the cornerstone of its industrial and cosmetic utility. Academic inquiry into processing methods scrutinizes how variations in heat, pressure, and solvent application influence the yield, purity, and chemical composition of the extracted oil, thereby affecting its efficacy for specific applications, such as its historical and contemporary use in textured hair care.

Castor Oil Processing, from an academic perspective, is a critical intersection of botanical science, chemical engineering, and deep cultural anthropology, revealing how ancestral knowledge systems intuitively harnessed complex biochemical properties for tangible community benefit.

Biochemical Transformations and Traditional Efficacy

The biochemical explanation of Castor Oil Processing provides insight into why certain traditional methods, despite their seemingly rudimentary nature, produced oils with superior properties for textured hair. Traditional methods, particularly those yielding Jamaican Black Castor Oil, involve roasting the seeds prior to extraction. This thermal pretreatment induces a series of pyrolytic reactions, contributing to the oil’s darker color and distinct aroma. While scientific literature often emphasizes cold-pressing for preserving nutrient integrity, the roasting process in traditional methods might facilitate the breakdown of certain compounds or alter the matrix holding the oil, potentially enhancing the release of beneficial elements or creating new ones.

For example, the alkaline ash produced from roasting and boiling the seeds, which is then often incorporated into the oil, could theoretically contribute to a slightly higher pH, which some traditional practitioners believe assists in cuticle lifting for deeper penetration into coarse, coily strands. While direct peer-reviewed studies on the precise chemical alterations induced by traditional roasting specific to textured hair efficacy are still developing, the enduring preference for these traditionally processed oils within Black and mixed-race hair communities serves as compelling anecdotal evidence of their perceived benefits.

The primary fatty acid, ricinoleic acid, present in castor oil, is unique due to its hydroxyl group. This structural feature contributes to the oil’s high viscosity and its ability to act as a humectant, drawing moisture to the hair and skin. In the context of textured hair, which is often prone to dryness due to its coiled structure and elevated cuticles, the humectant properties of castor oil are particularly advantageous. The oil forms a protective barrier, reducing transepidermal water loss from the scalp and locking moisture into the hair shaft, thereby enhancing pliability and reducing breakage.

Furthermore, ricinoleic acid has demonstrated anti-inflammatory and antimicrobial properties, which can promote a healthier scalp environment. A healthy scalp is a prerequisite for robust hair growth, and for communities with a historical reliance on castor oil for various ailments, its application to the scalp was a holistic approach to hair wellness. Research indicates that ricinoleic acid may influence prostaglandin pathways, specifically inhibiting prostaglandin D2 (PGD2), a lipid mediator associated with hair follicle miniaturization in certain types of alopecia.

This scientific observation lends a biochemical plausibility to the long-held ancestral belief in castor oil’s capacity to stimulate hair growth and thickness, especially for individuals experiencing thinning or slow growth. The precise interaction of ricinoleic acid with hair follicle biology remains an active area of research, yet the consistency of traditional claims across diverse cultures provides a compelling impetus for further investigation.

Ethnobotanical Lineages and Socio-Economic Impact

The academic meaning of Castor Oil Processing extends into its ethnobotanical and socio-economic dimensions, revealing its deep roots in ancestral practices and its role in community sustenance. The cultivation and processing of castor beans were not merely agricultural pursuits; they were integral to the social fabric and economic autonomy of many communities, particularly those in Africa and the African diaspora. Castor bean seeds were brought to the Americas by enslaved Africans as early as 1687, where their cultivation continued as a medicinal and cosmetic practice. This transfer of botanical knowledge and processing techniques during the transatlantic slave trade represents a powerful example of cultural continuity and resistance.

A specific historical example that powerfully illuminates Castor Oil Processing’s connection to textured hair heritage and Black/mixed hair experiences is the continued production of Jamaican Black Castor Oil (JBCO). This unique processing method, involving roasting the beans before extraction, is a direct legacy of African traditional practices. Enslaved Africans, forcibly transported to the Caribbean between 1740 and 1810, carried with them not only the castor seeds but also the intricate knowledge of how to process them for maximum benefit. This knowledge, often passed down through matriarchal lines, became a cornerstone of self-care and community health in the face of systemic oppression and a lack of formal medical access.

The reliance on traditional remedies, including JBCO, was a testament to the resilience and resourcefulness of African descendants. (PushBlack, 2023) The communal aspect of this processing, often involving women working together to shell, roast, and press the beans, fostered bonds and sustained economic activity in rural areas.

The economic significance of castor oil processing for traditional communities is not merely historical; it continues to play a role in contemporary livelihoods. In some regions, the cultivation and processing of castor beans serve as a source of income for small-scale farmers, often in semi-arid areas where other crops are less viable. While large-scale industrial production now dominates the global market, with India and Brazil being leading producers, the artisanal production methods persist, often catering to niche markets that value the heritage and traditional efficacy of the oil.

Case Study: The Socio-Economic Realities of Castor Cultivation in Contemporary Africa

While the historical narrative of castor oil processing often speaks to community resilience, contemporary economic realities can present new challenges. A recent investigation into large-scale castor cultivation projects in African countries, such as Kenya and the Republic of Congo, aimed at biofuel production, reveals the complexities of integrating traditional crops into global industrial supply chains. For instance, in Kenya, a project intended to recruit 25,000 small-scale farmers for castor production by 2023 only achieved 24.5% of its production target. Many farmers reported that the labor required for growing, picking, shelling, and drying the castor beans was not commensurate with the prices offered, leading to disappointment and insufficient operational support.

This case highlights a critical point: while castor cultivation holds immense potential for economic growth and sustainable development, the processing and market integration must respectfully account for the labor, traditional practices, and fair compensation for the communities whose ancestral knowledge underpins the very existence of these industries. The long-term success of such ventures, therefore, rests not just on agronomic yields, but on equitable partnerships that honor the human element of the processing chain.

The Spectrum of Castor Oil Processing: From Artisan to Industrial

The academic delineation of Castor Oil Processing also categorizes the various methods employed today, each with its own advantages and disadvantages concerning yield, purity, and the presence of specific compounds.

- Traditional Extraction (e.g. Boiling and Roasting) ❉ This involves manual or semi-manual steps like roasting, grinding, and boiling with water to separate the oil. This method is labor-intensive and typically yields a darker oil, such as Jamaican Black Castor Oil, often valued for its perceived holistic benefits. The oil recovery from such traditional methods can be lower, with one study reporting a percentage oil recovery of 38.84% from traditional Nigerian methods.

- Cold Pressing ❉ Seeds are mechanically pressed without the application of external heat. This method preserves the oil’s natural color, mild odor, and sensitive compounds. It is favored for cosmetic and pharmaceutical applications where minimal processing is desired.

- Solvent Extraction ❉ This industrial method uses chemical solvents, such as hexane, to extract oil from the crushed seeds or from the press cake left over from mechanical pressing. This method offers the highest oil yield but requires subsequent refining steps to remove solvent residues and other impurities.

- Combined Methods ❉ Often, a combination of mechanical pressing (hot or cold) followed by solvent extraction of the remaining cake is used in large-scale commercial production to maximize oil recovery.

Each processing pathway yields an oil with a distinct chemical profile and sensory attributes, influencing its market value and application. For textured hair, the cultural preference often leans towards the traditionally processed oils, whose history and sensory characteristics align with long-standing care rituals. The academic exploration of Castor Oil Processing, therefore, is not just about chemical efficiency but also about understanding the cultural and historical meaning embedded within each drop of oil, particularly for those whose heritage is intimately connected to its enduring legacy.

Reflection on the Heritage of Castor Oil Processing

The journey through the Castor Oil Processing, from its elemental origins to its academic scrutiny, ultimately brings us back to the heart of Roothea’s mission: a profound meditation on Textured Hair, its Heritage, and its Care. This exploration has revealed that the processing of castor oil is far more than a technical procedure; it is a living archive, etched into the very fibers of Black and mixed-race hair traditions. Each step, from the careful selection of seeds to the patient extraction of the oil, carries the echoes of ancestral hands and the whispers of generational wisdom. The meaning of this processing, for those who cherish their textured strands, is deeply personal and communal, a testament to resilience and cultural continuity.

The ‘Soul of a Strand’ ethos reminds us that hair is a powerful symbol of identity, a canvas upon which history is written. The enduring presence of castor oil in textured hair care, particularly the veneration of Jamaican Black Castor Oil, speaks to a heritage of self-sufficiency and profound knowledge. It highlights how, even in the face of immense adversity, ancestral communities preserved and adapted practices that sustained their physical well-being and cultural spirit. The very act of processing castor oil, whether through the slow, smoky roast of traditional methods or the clean precision of modern techniques, represents a continuous dialogue between past and present, between inherited wisdom and evolving understanding.

This legacy invites us to look beyond the immediate benefits of a product and to consider the stories it tells, the hands that cultivated it, and the communities it sustained. The enduring significance of Castor Oil Processing lies in its capacity to connect us to a deeper lineage of care, reminding us that true wellness is holistic, encompassing not only the scientific understanding of ingredients but also the cultural narratives that give them life and meaning. As we continue to honor and nourish textured hair, we honor the ingenuity, the perseverance, and the boundless spirit of those who came before us, their wisdom encapsulated in every drop of this remarkable oil.

References

- Oluwole, F. A. Abdulrahim, A. T. Aviara, N. A. & Ndahi, S. N. (2012). Traditional Method of Extracting Castor Oil. Continental Journal of Engineering Sciences, 7(2), 6-10.

- Burdock, G. A. Carabin, I. G. & Griffiths, J. C. (2006). Castor oil: A review of current safety data. Food and Chemical Toxicology, 44(11), 1789-1798.

- Scarpa, A. & Guerci, A. (1982). Castor bean (Ricinus communis L.) in ancient Egyptian medicine. Journal of Ethnopharmacology, 6(1), 1-13.

- Ando, A. Natsui, H. Yabuta, M. & Watanabe, K. (2004). Conjugated linoleic acid production from castor oil by Lactobacillus plantarum JCM 1551. Bioscience, Biotechnology, and Biochemistry, 68(11), 2383-2386.

- Marte, L. (1981). Ricinus communis L. (castor bean). In Medicinal Plants of the West Indies. University of Puerto Rico Press.

- Roetheli, J. C. Kincaid, R. E. & Dobbins, C. L. (1991). Castor bean production and marketing in the United States. Agricultural Economic Report, 649.

- Deacon, H. J. (1986). The history of the Ricinus communis L. in South Africa. South African Journal of Science, 82(2), 79-82.

- Oluwole, F. A. (2010). Design and fabrication of a castor seed shelling machine. International Journal of Engineering Science and Technology, 2(10), 5174-5178.

- PushBlack. (2023, September 23). Why Jamaican Black Castor Oil Is Rich in Black History. PushBlack.

- PushBlack. (2023, November 23). Why Jamaican Black Castor Oil Is Rich In Black History. YouTube.

- CABI Compendium. (2024). Ricinus communis (castor bean).

- Qhemet Biologics. (2024, September 28). The History & Benefits of Castor Oil.

- Ambuja Solvex. (2022, October 14). Jamaican Black Castor Oil: Surprising Benefits & Facts.

- JBDC. (2022, July 25). Striking Gold With Castor Oil.

- Chowdhury, S. & Das, S. (2018). Physiological and Medicinal Properties of Castor Oil. ResearchGate.